Coolant performance strongly depends on how correctly it is mixed. Water quality, coolant concentration and proper emulsion preparation determine how stable the coolant operates, how long the emulsion lasts and how reliably CNC machines perform.

An incorrectly mixed coolant emulsion can lead to foaming, corrosion, high consumption, unstable processes and reduced tool life. This guide explains step by step how to mix metalworking coolant correctly, which role water hardness and chloride content play, and how to achieve a stable coolant emulsion in real CNC machining conditions.

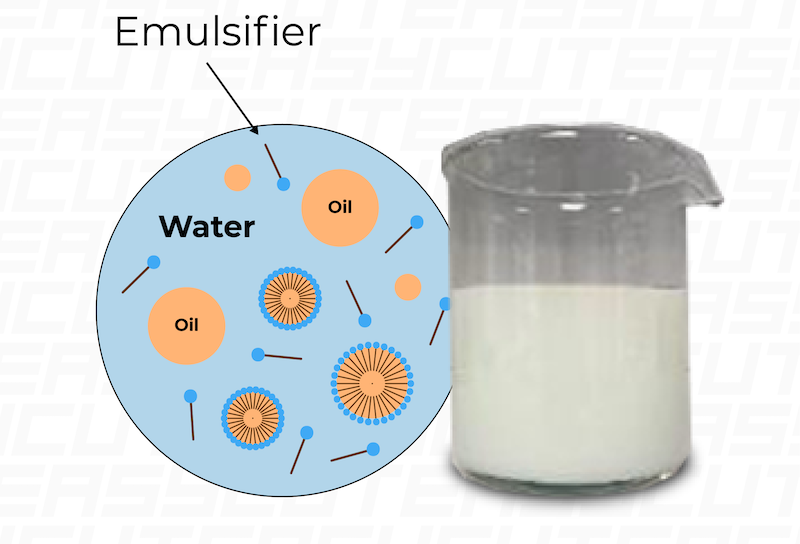

Figure: Fresh coolant emulsion and emulsifier principle

A coolant emulsion always consists of two main components: coolant concentrate and water. Water accounts for more than 90 percent of the total volume of a ready-to-use emulsion. For this reason, water quality has a direct impact on emulsion stability, actual coolant concentration and overall system behavior during operation.

Water hardness, chloride content and cleanliness influence foaming, corrosion risks, machine hygiene, tool life and coolant consumption. Even a high-quality coolant concentrate cannot perform properly if the water quality does not match the application.

Good water results in a stable coolant emulsion, uniform coolant concentration in the tank, longer service life and more reliable CNC processes. Poor or untested water leads to unstable emulsions, frequent concentration corrections and avoidable process issues.

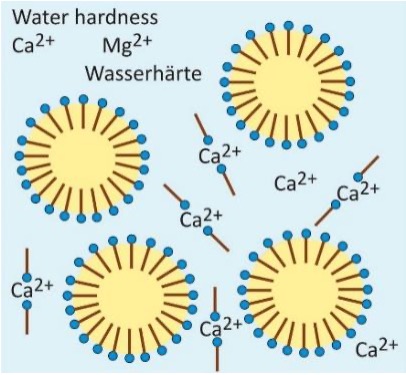

Water hardness describes the amount of dissolved minerals in water, mainly calcium (Ca²⁺) and magnesium (Mg²⁺) ions. These ions react directly with the coolant emulsifiers and influence emulsion stability, foam behavior and effective lubrication.

If the water is too soft, the emulsion may foam excessively, leading to air entrainment, pump problems and unstable concentration. If the water is too hard, poorly soluble compounds such as lime and lime soaps can form. These deposits reduce corrosion protection and destabilize the emulsion.

Lime soaps are created by reactions between anionic emulsifiers in the coolant concentrate and calcium ions in the water. This directly affects emulsion fineness, foam control and the long-term service life of the coolant.

Figure: Calcium and magnesium ions and their role in water hardness

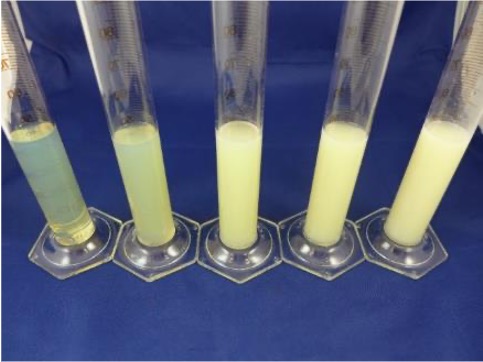

Depending on water hardness, a coolant emulsion behaves differently in the tank. Hardness affects foaming, emulsion stability, corrosion protection and the overall maintenance effort during daily operation. The following ranges provide practical guidance:

Soft water (0–8 °dH)

Very soft water often causes increased foaming, especially at high pump pressures or with air turbulence in the system. Lubrication performance may become unstable as the emulsion reacts more sensitively to concentration changes.

Medium water (8–14 °dH)

This range is considered ideal for most water-miscible coolants. The emulsion remains stable, low-foaming and provides a good balance between cooling, lubrication and corrosion protection. Coolant concentration and sump life are easiest to control in this range.

Hard water (14–20 °dH)

With increasing hardness, the risk of lime soap formation, system deposits and reduced corrosion protection increases. The emulsion may become unstable and require more frequent adjustment.

Very hard water (>20 °dH)

Very hard water often leads to heavy mineral deposits, shortened emulsion life and higher maintenance effort. In such cases, treated water or adapted coolant systems are strongly recommended.

Figure: Water hardness test strips and 0–30 °dH scale

Water quality in Germany varies significantly by region and can differ considerably from city to city. A coolant that runs stable in one region may cause issues in another region with the same settings.

Southern Germany typically has very hard water due to high mineral content. Northern regions often feature softer water, while central and eastern areas show mixed hardness levels.

Figure: Water hardness map of Germany

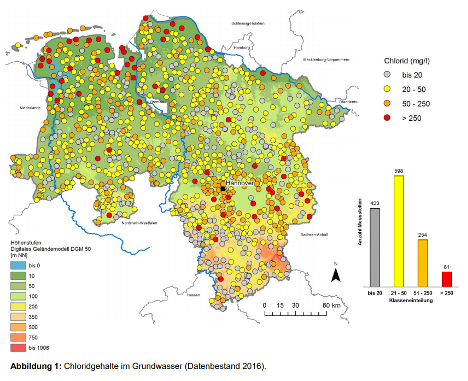

Chloride levels also vary regionally and influence corrosion behavior, emulsion stability and coolant life. Some regions naturally show elevated chloride concentrations, which must be considered when mixing coolant.

Figure: Chloride concentration map of Germany

Because of these regional differences, workshops should rely on local water data instead of assumptions. Only by considering both water hardness and chloride content can a stable coolant emulsion with consistent concentration be achieved.

Chloride ions (Cl⁻) are another critical factor for coolant emulsion stability and corrosion protection. Unlike water hardness, chloride-related damage often develops gradually but can cause significant long-term problems.

High chloride levels increase the risk of corrosion on machine components, guides, fixtures and workpieces. At the same time, the emulsion may become unstable and separate into oil and water phases over time.

Low chloride levels support longer emulsion life, more stable corrosion protection and a more consistent coolant concentration in the tank. High-alloy steels, aluminum alloys and precision components are particularly sensitive.

If chloride levels are elevated, using treated water such as reverse osmosis (RO) or deionized (DI) water can significantly reduce the load and improve emulsion stability.

Figure: Corrosion caused by elevated chloride levels

Even with suitable water hardness and low chloride levels, a coolant emulsion can become unstable if the system is contaminated. Cleanliness plays a central role in emulsion life, actual coolant concentration and process reliability.

Rust particles, chips, abrasion, dirt and residues from old emulsions accelerate coolant degradation. They promote microbial growth, change pH values and destabilize the emulsion over time.

Contaminated tanks often lead to increased consumption, unpleasant odors, foaming and uneven concentration throughout the system. In practice, coolant problems are frequently blamed on the product, while the real cause is system contamination.

Clean machine tanks, regularly cleaned mixing containers and effective filtration are therefore essential for stable coolant emulsions and long service life.

Figure: Contaminated coolant tank in practice

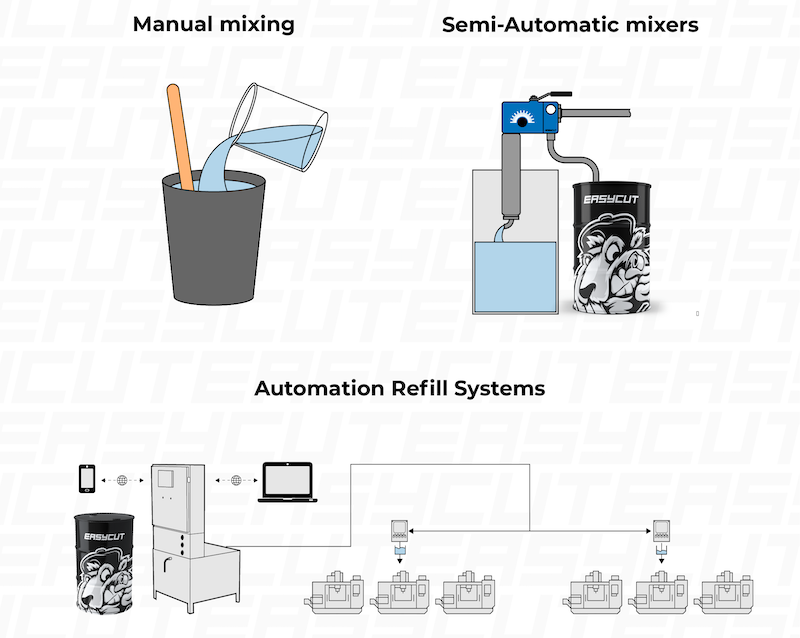

Two main methods are used to mix metalworking coolants: automatic mixing systems and manual emulsion preparation. Both methods are valid, depending on consumption volume, equipment size and process requirements.

Automatic mixing systems are mounted directly on the coolant container (canister, drum or IBC) and use water pressure to draw in coolant concentrate and mix it with water. The ready emulsion is fed directly into the machine tank or supply system.

This method ensures uniform emulsion quality and stable coolant concentration, especially in workshops with high consumption or multiple CNC machines.

Manual mixing is suitable for small workshops, single machines or occasional refills. Here, emulsion quality depends entirely on operator discipline.

Special care is required, as incorrect mixing ratio or sequence can immediately lead to unstable emulsions. Basic rule: Always add coolant concentrate to water, never water to concentrate.

Figure: Different coolant mixing methods

When mixing coolant manually, a clean and consistent procedure is essential to achieve a stable emulsion with correct concentration. The following steps have proven effective in practice:

Understanding water quality, coolant emulsion behavior and correct concentration is essential for stable and cost-efficient CNC machining. Good water, proper mixing and clean systems reduce consumption, prevent failures and extend tool and machine life.