...back to the Coolant Articles

Metalworking coolants (MWF), also known as cutting fluids or coolants, are a key part of modern machining. Around 90% of CNC machines run with coolant to remove heat, reduce friction, extend tool life, and protect workpieces from corrosion. Only a small share of operations run dry, often supported by compressed air.

Coolants help with heat removal, lubrication, chip evacuation, and process stability – which supports dimensional accuracy and surface finish. To choose the right coolant, it helps to understand the main coolant families and the chemistry behind water-miscible coolants.

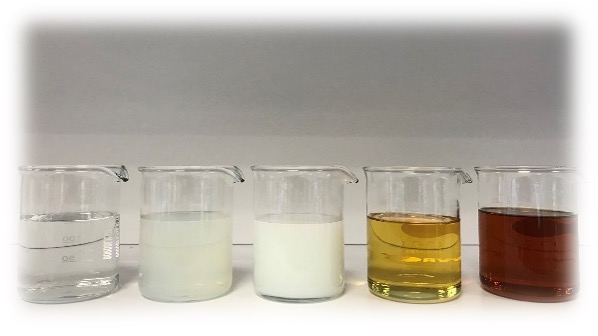

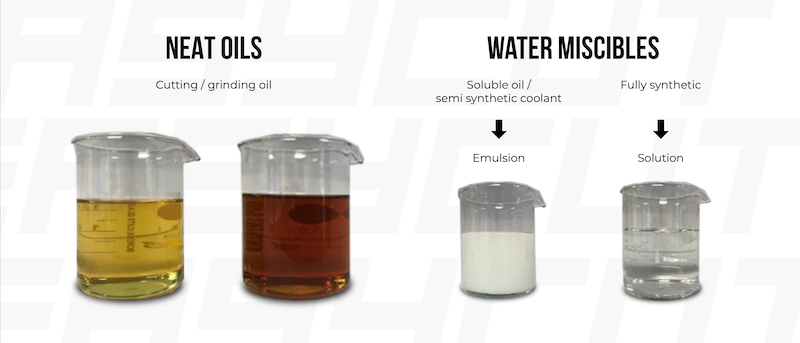

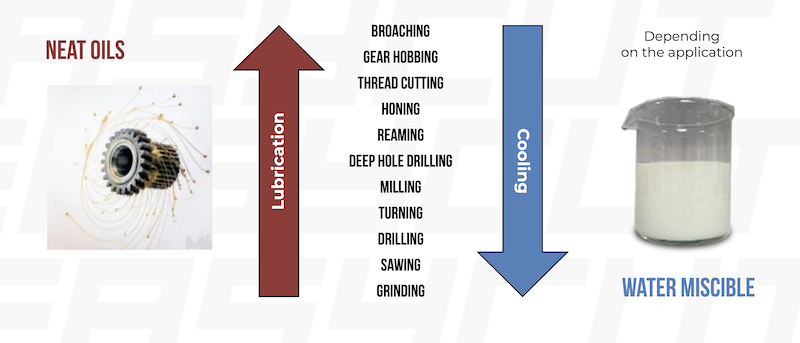

In practice, metalworking coolants can be grouped into two big families: neat oils (not water-miscible) and water-miscible coolants (emulsions or solutions).

Both families have typical use cases and strengths depending on the machining process and materials.

Neat oils include cutting oils, grinding oils, and forming oils that do not mix with water. They can be mineral oils, vegetable-based ester oils, or synthetic oils. They are used where maximum lubrication is required, for example gear cutting, broaching, deep-hole drilling, Swiss-type lathes, or precision grinding. A special category is dielectric fluids used for EDM (electrical discharge machining).

Neat oils deliver very high lubricity, good surface finish, and stable viscosity, but they have limited cooling capacity. They can also generate oil mist, so proper extraction and correct disposal are important.

Most modern CNC machines run water-miscible coolants. They are typically mixed at 3% to 15% concentrate in water and form an emulsion or a solution. The big advantage is that water provides strong cooling, while the .

Water-miscible coolants became the standard because they combine good cooling with acceptable lubrication, are relatively cost-effective, and help keep the workplace cleaner. To understand why different water-miscible coolants behave differently, it is worth looking inside the concentrate.

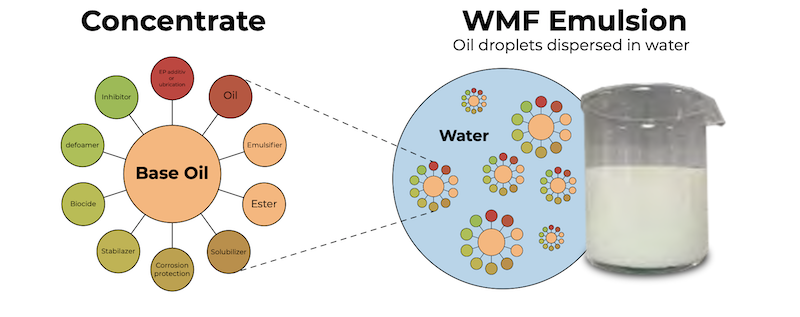

A coolant concentrate is not a simple “oil and water mix”. It is a designed system of components that define performance:

The base is the base oil or base fluid, for example mineral oil, ester oil, synthetic oils (PAO, PAG), or polymers such as glycol. This base strongly affects lubricity, behavior in mixing water, and compatibility with different materials.

Emulsifiers keep fine oil droplets stable in water and influence emulsion fineness, foam tendency, and separation stability. Corrosion inhibitors protect machine parts, chips, and workpieces. EP and AW additives (Extreme Pressure / Anti-Wear) are important for tough materials such as stainless steel or titanium. Additional components improve biostability, reduce foam, and extend emulsion life.

Imagine how important the quality of the base oil, the additives, and the laboratory control is during development – not to mention the quality of the water you use later for mixing. For water quality and correct mixing practices, see our guide “Mixing Coolant and Understanding Water Quality”.

Water-miscible coolants can be grouped into five main categories. Each type has typical strengths and limitations depending on the material mix and machining process.

Semi-synthetic coolants usually contain about 5% to 49% mineral oil in the concentrate. They combine good cooling with solid lubrication and typically form a stable, low-foam emulsion.

In practice they offer wide coverage: turning, milling, drilling, and grinding of steel, cast iron, and many aluminum alloys can be handled with a well-selected semi-synthetic coolant. Biostability and tank life are usually strong as well.

In the EASYCUT range, typical examples are the universal UNI301, the aluminum-optimized PRO302, and BASE201 for lighter applications and grinding.

Ester-based coolants use vegetable ester oils as the lubricating component. They combine strong lubricity with good cooling and tend to run “clean” in many applications. They can be attractive for demanding aluminum machining or when sustainability is a priority.

In many cases, tool life and surface finish can improve, while reducing environmental and workplace load. The downside is usually cost – these products tend to sit above classic semi-synthetics. An example in the EASYCUT range is VEG001.

High-mineral-oil emulsions often contain about 50% to 80% mineral oil in the concentrate. They were common in the past but are increasingly less used in modern CNC environments.

They can offer decent lubrication and a low price per liter, but often struggle with cooling performance, stability, cleanliness, and bacterial susceptibility. Flushing performance can be weaker, and aluminum may darken. CNCmarket.de does not offer classic high-mineral-oil emulsions.

Synthetic coolants contain no mineral oil. Traditional synthetics are water-based with polymers and additive packages. They are known for very strong cooling, good flushing, and high resistance to bacterial growth.

Typical use cases include grinding or machining with very high thermal loads. Lubricity is lower, corrosion protection can be more sensitive, and aluminum can discolor. Synthetics can also be sensitive to concentration mistakes, so refractometer control is important.

Polymer-based high-tech coolants use polymer base fluids such as glycol and also contain no mineral oil. They can deliver excellent cooling, good lubricity, and very high stability, with minimal residues on parts and machine surfaces.

They are often used for plastics, composites, and applications where extremely clean machining, long tank life, and stable behavior are critical. They are usually premium-priced and may require good water quality and filtration.

The table below summarizes the key characteristics of each coolant type. The star ratings are a practical guideline, not a laboratory specification.

| Type | Cooling | Lubrication | Stability | Foam | Material compatibility | Cost |

|---|---|---|---|---|---|---|

| Semi-synthetic | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★☆ |

| Ester-based | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★★ | ★★☆☆☆ |

| High mineral oil | ★★☆☆☆ | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ | ★★★★★ |

| Synthetic | ★★★★★ | ★★☆☆☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★★☆ |

| Polymer-based | ★★★★★ | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

Choosing the right coolant depends on your materials, machining processes, and shop priorities. For many workshops, a strong semi-synthetic coolant is the best starting point because it balances cooling, lubrication, and stability. If surface quality and sustainability are key drivers, an ester-based coolant can make sense.

For grinding or machining with very high thermal loads, synthetic coolants often have an advantage. Polymer-based high-tech coolants come into play where extremely clean machining, long tank life, and special materials like plastics or composites are important. Classic high-mineral-oil emulsions are increasingly outdated and play a smaller role in modern CNC shops.

In a shop machining mostly steel and cast iron with occasional aluminum, EASYCUT UNI301 is a typical all-round choice. The emulsion is stable, low-foam, and suitable for many machines.

If the focus is clearly on aluminum, for example in serial production of housings or profiles, EASYCUT PRO302 with optimized corrosion protection and aluminum compatibility can be the better option. For grinding or lighter machining, EASYCUT BASE201 is often a cost-effective solution.

Shops with a strong focus on environmental topics and workplace hygiene can consider the ester-based EASYCUT VEG001, as long as the application benefits from the higher lubricity and cleanliness and the budget supports it.

If you want to go deeper into water quality and mixing practices, see our guide “Mixing Coolant and Understanding Water Quality”.

Find suitable coolants for your application in our product range: